The future is collaborative: a partnership rethinking architectural design by incorporating robotics and automation

Carleton University and ABB Robotics Canada collaborate to build better and faster through innovation, research, and talent development

By: Ahmed Minhas

November 20, 2023

Since the industrial age, machines have required constant human guidance, but we’re now living in a world where machines and humans seamlessly collaborate, operating together without constant supervision. It’s all thanks to remarkable strides in robotics and automation.

In the summer, the Carleton Sensory Architecture and Liminal Technologies (CSALT) Laboratory, led by Associate Professor Sheryl Boyle, embarked on a pioneering journey. The lab integrated two ABB Robotics Canada “GoFa” robots, affectionately named Thelma and Louise, to explore robotic collaboration and reshape the future of architecture, engineering, and construction (AECO).

Provided through a generous three-year equipment loan, these cobots (collaborative robots) work alongside the CSALT Lab research team. Carleton University and ABB Robotics Canada (ABB) have partnered to redefine design workflows by seamlessly integrating robot collaborators into the heart of architectural creativity.

“Through a partnership with the CSALT Lab at Carleton University, future architects can gain a better understanding of what a robot can do, in relation to the construction industry. This will allow them to better integrate robotic automation into designs and building processes in such a way that their work will speed up construction, reduce raw material waste and meet the demands of the market,” explained Nicolas Durand, vice president and general manager at ABB Robotics Canada.

ABB not only provides the cobots but also offers on-site support for seamless operation. During the summer, an ABB educator conducted two week-long programs teaching lab members how to code, use cobots, and utilize ABB’s RobotStudio Suite for hands-on experience with visualization software for simulated operations.

The team’s initial goal is to study the workflow of smaller cobots; learning how they navigate, the sequence of their movements, and the code that controls them. Once they master working with these cobots, they’ll move on to ABB’s larger offerings.

“Designers must possess a deep comprehension of workflows to shape and even challenge them,” said Dr. Boyle. “Without grasping the underlying logic of a tool, designers cannot effectively question or harness its capabilities. Acting on insights that can reshape practices and ultimately influence our living spaces hinges on this understanding.”

Cobots Take on the Heavy Lifting

ABB’s partnership with academic and research-intensive institutions like Carleton trains future AECO professionals on how to use their tools, promoting automation and robotics adoption. It also helps ABB explore new cobot applications, leading to the development of improved products, based on insights from researchers.

The cobots play an integral role in the lab, constructing scale models of buildings and architectural elements. Through their presence, they take over the “heavy lifting” of precise placement and alignment tasks, which allows architects more time for design and component innovation. Thanks to the underlying software guiding the cobots, architects can easily fine-tune their designs on the go.

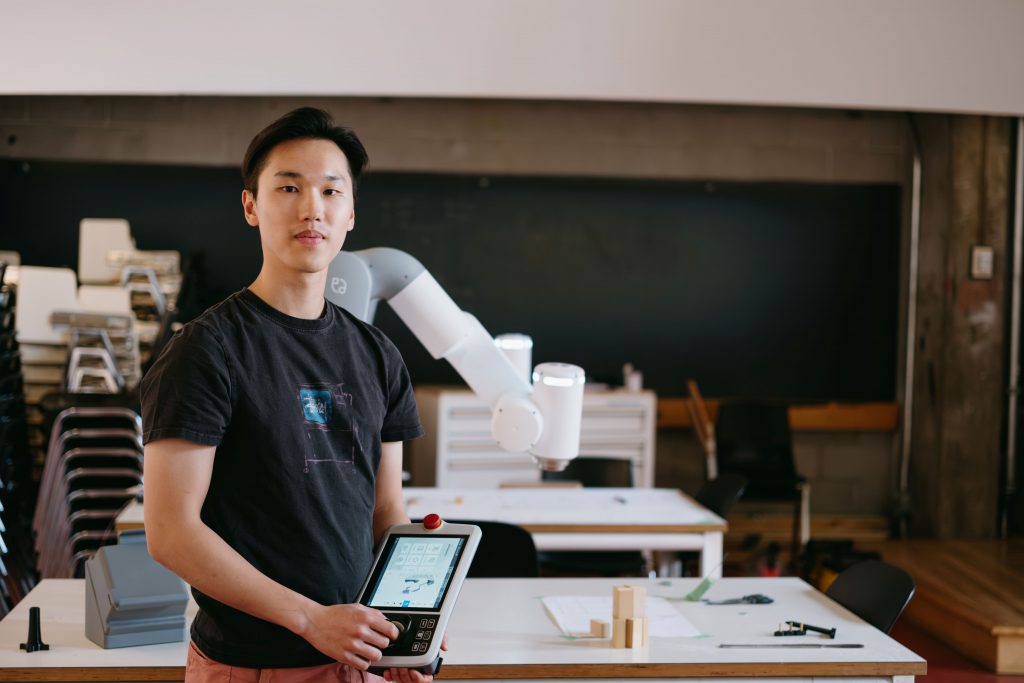

“When it comes to the balance between automation and innovation, automation liberates architects to invest more time in conceiving innovative designs and ideas,” noted Adonis Lau, team leader and research assistant at the CSALT Lab. “My understanding of this concept has deepened while collaborating with the cobots in the lab.”

Dr. Boyle and her lab recently secured a Mitacs Accelerate grant to support Lau for a two-year project, “Design for Manufacturing & Assembly (DfMA) for Architects with Industrial Robots.” Leveraging insights by working alongside ABB’s cobots, this project will inform how architects can effectively incorporate robots into design-thinking activities.

Breaking Down Silos Through Talent Development

Dr. Boyle underscores the pivotal role architects play in construction, however, prevailing silos among AECO professionals often result in overlooking critical design and construction insights.

“We can’t solely rely on individual craftspeople to build the structures of the future. The building process needs to be a collective effort, drawing from diverse disciplines to maximize the potential of space from design to fabrication and assembly.”

This partnership goes beyond research; it also nurtures talent. Students in the lab greatly benefit from working with ABB’s cobots. Philippe Fleishmann, robotics technician from ETH Zurich, who assisted with cobot setup during his three-month sabbatical at Carleton, praised the students’ PhD-level work and contributed to enhancing their skills through open-source software development, drawing from his experience at ETH Zurich and ABB.

Canada faces a housing crisis due to a shortage of skilled workers, with around 20 percent of the construction workforce set to retire in a decade. Ontario alone has 20,000 vacant positions. This is where robotics and automation may provide solutions to bridge the skilled labour gap.

“Addressing this skills gap necessitates the adoption of robotic technologies and the cultivation of a new generation skilled in collaborating with these technologies,” stated Durand. “We’re partnering with institutions like Carleton University to inform a robotic inclusive mindset to bridge this gap and equip the next generation with the skills to collaborate with automated robotic systems.”

While robotics may not be the traditional focus for architects, emerging automation technology underscores their importance. Integrating cobots into architectural education and research is essential to prepare the next generation to confidently engage with this advanced technology.

“We’re working with robots to create a generation of architects who are well-versed in the digital craft of fabrication. To achieve this, we must first grasp the basics of how the robot functions before we can experiment with custom code, commands, and ultimately, designs,” Dr. Boyle emphasized.

“Cobots offer a unique opportunity to bridge the knowledge gap and break down the adoption barriers that prevent architects, engineers, and construction workers from leveraging the advantages of robotics to build innovative, safer and more sustainable structures,” affirmed Durand.

“Collaboration is the key to propelling the future of the construction industry and a significant part of developing interdisciplinary talent that can seamlessly integrate with robotics. We look forward to the novel and imaginative cobot applications in architecture conceived by Dr. Boyle and her team at the CSALT Lab.”